Tool Technology for Resin-Transfer-Molding (RTM)

BBG Group

As an experienced system partner, we design and manufacture high-precision tools for the Resin Transfer Molding (RTM) process – from simple prototype molds to series-production tools, optionally equipped with integrated process data acquisition and analysis.

We support our customers throughout the entire development and production process – from the initial concept idea to the commissioning of the fully reliable production system, and beyond with customized service solutions.

RTM is a key technology for lightweight design

Fiber-reinforced plastics – particularly carbon fiber reinforced plastics (CFRP) – have become firmly established across many industries. At the same time, sustainable material systems such as bio-based fibers and resins are gaining importance and are increasingly being used as alternatives or supplements. In addition to the aerospace and automotive industries, many other sectors are taking advantage of the benefits offered by lightweight composite components.

To manufacture such lightweight parts efficiently and with consistent quality, the Resin Transfer Molding (RTM) process has proven to be particularly suitable. It enables high dimensional accuracy, short cycle times, and reliable results even for complex geometries – characteristics that are crucial for structural components in safety- and function-critical applications. Other processes, however, may offer advantages when producing single parts, very large components, or extremely thin-walled structures.

Manufacturing systems for CFRP window frames

Our production technology is also used in aircraft manufacturing. In BBG’s manufacturing systems, CFRP window frames are produced using the RTM process. The focus here is on process reliability, reproducibility, and compliance with the highest quality standards – requirements that are indispensable in the aerospace industry.

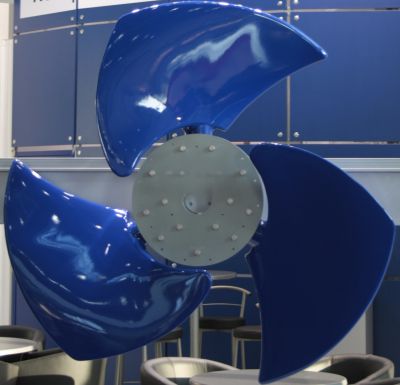

RTM molds and tooling for rotor blades

For industrial ventilation systems, we have developed RTM toolings for the production of rotor blades. In this process, rigid foam cores are encapsulated with glass fiber reinforced plastic (GFRP) using the RTM method. The result is precise components with excellent dimensional accuracy

High-Pressure-RTM tooling for hydrogen storage tanks

Another field of application is HP-RTM tooling for the production of hydrogen tanks for passenger cars and commercial vehicles. These tanks must be extremely pressure-resistant and reliable. With our tooling technology, they can be manufactured cost-effectively and with consistently high quality.

Your application could be next

Your challenge becomes our challenge. We support you with well-engineered tooling – precise, robust, and tailored to your process.